|

|

The Blakely Burl Tree Project: The

Story

|

The Blakely Burl Tree Project:

From The Ground Up

by Terry Martin |

THE SAWMILL

The Super AX

The Blakely Burl Tree arrives at Cross Sawmill, Iron City, GA

Photo: John McFadden

It’s our first day at Steve Cross’s

sawmill. A piece of the Burl Tree is suspended on straps from a forklift, and

Mark and Gary are debating where to take the first cut.

Mark: We can saw through the top of the crotch so the next cut gives us a nice

cross section.

Lifting the Blakely Burl Tree off the truck.

Photo: John McFadden

I’ve been listening to Mark and Gary talk about how they're planning to cut the

wood and my attention

starts to wander. I look around at Steve’s property, from the house near the

woods down to the road to Iron City that cuts across the bottom of his land. As

I watch, a file of cotton picking machines chugs along the road to their next

contract. I walk away from Mark and Gary and everywhere I look there are

derelict machines: old buses, cars, trucks and forklifts. Scattered around the

property are stacks of sawn lumber of every width and thickness imaginable.

That’s what Steve does, he’s a fifth-generation sawyer.

Steve Cross, fifth generation sawyer at the controls of his "Super-Ax"

sawmill.

Photo: John McFadden

While Mark and Gary continue their discussion, Steve joins me for a tour of his

domain. In Blakely, Steve was deeply involved in the process of harvesting the

burl tree, but his natural courtesy and shyness prevented him from pushing

himself forward. In contrast, Steve lights up with enthusiasm as we walk around

his own land. He wants to show me all the things that define his world. He shows

me the house he built, where he lives with his wife and three children. We walk

amongst the stacked wrecks of cars and he tells me, in a masterly

understatement, that he "renovates and reconfigures used equipment that others

might call junk."

The film Crew's motor home is setup in the Cross family's front yard during

filming. Photo: John McFadden

Steve shows me his grandfather's steam engine, his Volkswagens

filled with old chainsaws, the bus that has been in a head-on collision, and

fork lifts everywhere in every state of decay, disassembly and disrepair. Steve

is obsessed with forklifts and the miracles he can work with their salvaged

hydraulic rams.

Steve Cross with his grandfather's steam engine. Photo:

Mark Lindquist

In the crisp fall air we circle back to the sawmill. Mark and Gary seem to have

reached agreement about what to do, so Steve joins them. I stand back and try to

take in Steve’s piece de resistance, the Super Ax Sawmill. From afar it looks

like an old steamship sailing across the flats at full steam. Closer up it is

more like a cross between Water World and Willy Wonka’s Chocolate Factory.

The Super-Ax sawmill, hand built by Steve Cross.

Photo: John McFadden

The

platform of the saw is made of nine semi-trailer beds, lined up to form a vast

working surface strewn with a museum's load of antique hand tools that Steve

uses to make adjustments to the saw. The mill itself rears overhead and the

first thing that catches my eye is the stacked forklifts that act as

counterweights to stabilize the whole structure. There are ladders that seem to

go nowhere and on the top there is a beer keg used as a fuel tank. There are

axles, connectors, platforms, turnbuckles, and hydraulic lines running

everywhere. I can see that when Steve has painted a wheel, he paints every spoke

a different color!

The Super-Ax sawmill, hand built by Steve Cross.

Photo: John McFadden

When you see the turnbuckles and chains that hold it all

together, you might be tempted to think it is all just add-ons, placed to

correct faults and problems. In fact Steve had the whole thing planned in his

head before he started and knew exactly where each component would be. "I didn't

need to draw it," he says. "I would have finished building it before I had it

drawn." The mill head can cut 60" diameter logs and Steve believes he can

accommodate larger logs if required. The 32" diameter band saw wheels run on

semi hubs and are dynamically balanced with lead shot in liquid-filled tubes.

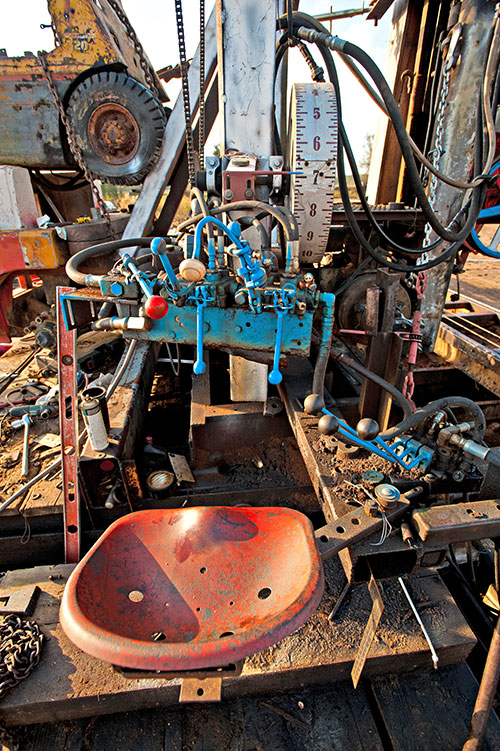

Mark and Gary guide the first log into position for cutting and it’s time for

Steve to start his mill. He sits on a tractor seat and pulls handles and levers.

He is surrounded by indicators to show how many inches he’s cutting, gauges,

little magnets with measuring tapes attached, buttons, levers, and even a little

bobble-headed doll that wobbles as the machine fires up. Steve waves his hand at

the buttons and shouts to me over the rising noise of the mill, “The big red one

is the stop button!”

The main controls of the Super AX.

Photo: John McFadden

Mark Lindquist (left) and Gary Stevens loading the Blakely Burl Tree onto the

carriage

Photo: John McFadden

Steve becomes more alive, looks around with a huge grin on his face, then

becomes a picture of intense concentration as he throws the lever to feed the

first log into the mill. When the log runs forward on the laser-leveled tracks,

the whole monstrous machine whiffles and snorts, fuel feeds from the beer keg

fuel tank, lubricating water sprays everywhere and sawdust jets out into the air

as the blade slices the log. Steve plays the saw like some ancient pipe

organ—pulling levers, pushing knobs, adjusting feed, and coaxing the Super Ax to

work its magic.

Cutting the Blakely Burl Tree Log. Photo: John McFadden

The first main cut through the trunk revealing amazing grain.

Photo: John McFadden

Top view of the main slab on the carriage.

Photo: John McFadden

Mark Lindquist (left) with Gary Stevens removing the top cut.

Photo: John McFadden

Everyone falls into the time-honored rhythm of the sawyer: run the log back,

turn it, run it through the saw again, flip the newly cut flitch aside, run the

log back…..but just when I think it will go on like this for the rest of the

day, Steve decides he is unhappy with the tracking of the saw. He engages a

hydraulic ram and—to our absolute, gobsmacked amazement—the whole saw gets up

and walks! Alternating hydraulic rams lift the tens of thousands of pounds on

huge feet and he walks the saw closer to the log to avoid a bump on the opposite

side. Then, with a sigh and a whistle, it settles down and continues the cut.

Amid all this commotion the blade runs as smoothly as a hot knife through

butter.

Stanley Houston (right) with Mark Lindquist, Chris Smith and Steve Cross at

the mill. Photo: John McFadden

For several hours Mark and Gary are furiously busy lifting and turning logs,

lining up cuts, moving sawn timber and exclaiming loudly as more and more

amazing wood grain is revealed by the long saw cuts. As the wood is

progressively cut it is moved to a storage shed and carefully stacked. While all

this has been going on Chris has been sweating away in the background, preparing

spacers to allow the wood to dry uniformly. We all lend a hand and soon the sawn

timber starts to mount up. This stacked wood is a testament to Steve's raw

genius. I don’t recall a more entertaining day for many years.

Chris Smith placing stickers on the wood to help with drying. Photo:

Mark Lindquist

|

|